This is a measuring instrument that can visualize the noise level in metal lines when replacing core wires as a tool to prevent noise-induced failures.

When a metal line failure is repaired, extremely low level noise can be measured, even though it cannot be identified through line testing using a circuit inspection tester and line test handset.

The measured noise level is displayed on an LED display, thus allowing an easy pass/fail decision.

A monitor speaker with automatic level control is incorporated, allowing checks of core wire identification signals and noise in an audible band at -70 dBm or higher.

The compact size LCK-601 allows users to hang it around their neck.

Dry batteries can support extended use.

The minimum measurement level is -70 dBm.

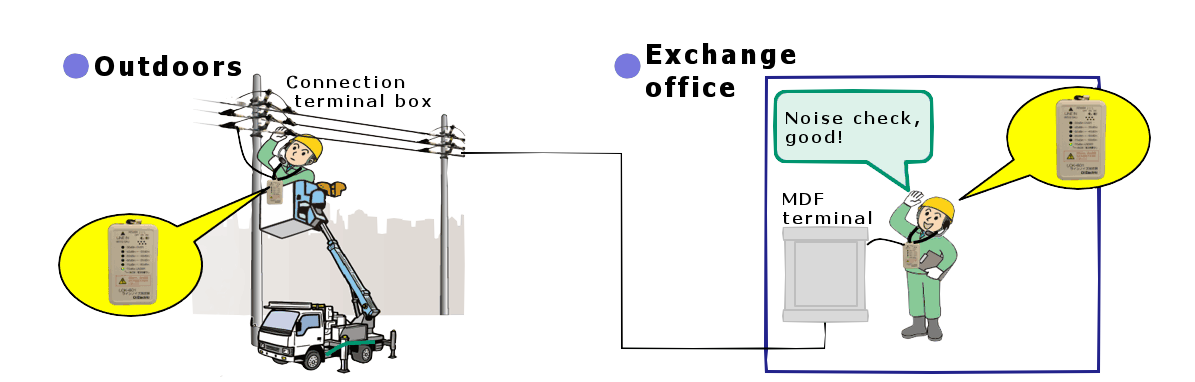

Configuration example

Main Specifications

| Item | Specifications | Remarks |

|---|---|---|

|

Input impedance

|

Within 600Ω±5% (balanced) (Input terminal: crocodile clip) |

|

|

Absolute maximum input level

|

5dBm |

|

|

Level measurement range

|

-70dBm ~ -30dBm AND -30dBm OVER、-70dBm UNDER |

|

|

Measurement accuracy

|

Within ±2 dB |

|

|

Measured value display

|

LEDs are used to display the following range |

|

|

Speaker

|

Sounds when the power switch is set to the speaker ON position |

|

|

Power supply

|

AA batteries × 2 |

|

|

Guaranteed temperature/humidity performance

|

Temperature: 0°C to 40°C; Humidity: 20% to 85% (Note: in an environment with no condensation) |

|

|

Dimensions/mass

|

Dimensions: H115 × W69 × D28 mm (The projection is not included) |